- Front page

- About Us

- Laser machine

Fiber Laser Cutting Machine

Fiber Laser Cutting Machine

Laser cleaning machine

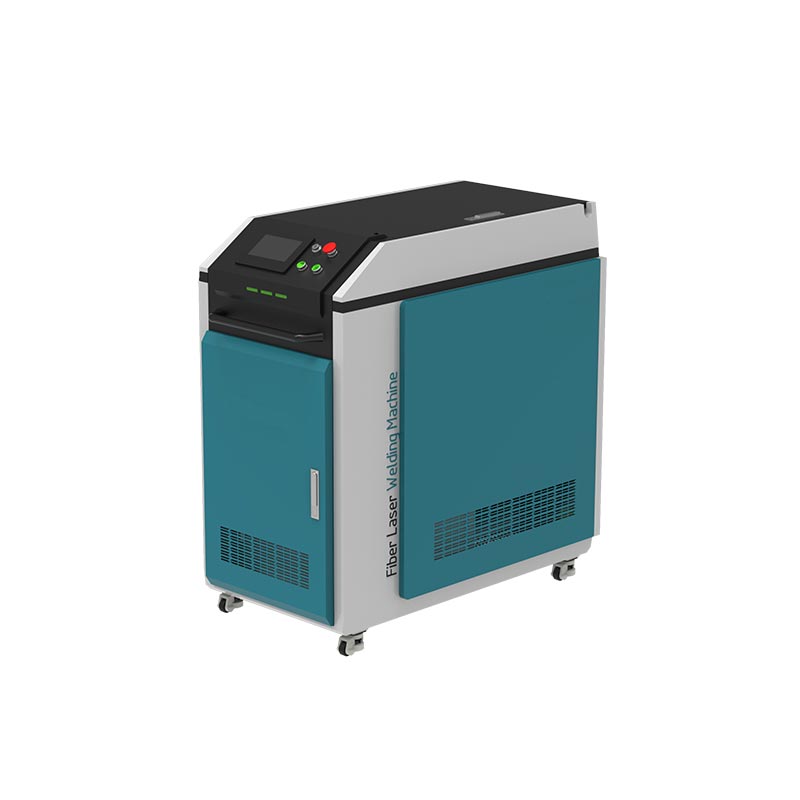

Laser cleaning machine Laser welding machine

Laser welding machine Bending Machine

Bending Machine

- Accessories

- Application

- Contact Us

- Featured

|

MACHINE MODEL |

QUANTITY (SET) |

PRICE (USD) |

Warranty |

|

LXW Reci :FOB:QINGDAO |

1 |

****** |

2 years |

|

Machine body |

New design of our company CE standard Heavy duty machine frame | ||

|

Controller |

Reci controllerLED touch panelMother language customizedReci laser gun | ||

|

Laser system |

Fiber laser source Reci 1500W | ||

|

Cooling system |

Air cooling system | ||

|

Other important parts |

France Schneider Electric DeviceWire feederOutput cable length: 10m | ||

|

Consumable parts |

10xProtective lens10xWelding nozzles | ||

|

Service |

Manual +Video2-year warrantyOversea service24 hours online service | ||

|

Dimension (L*W*H)mm |

800x750x900mm |

N.W/Kg |

65KG |

|

CBM(m3)/set |

1CBM |

G.W(kg) |

75KG |

|

Packing |

Plywood package |

Delivery time |

5-10 work days |

|

Payment |

Alibaba Trade Assurance, T/T, Western Union, L/C | ||

|

Model |

LXW |

|

Laser source |

Reci |

|

Working life of fiber module |

More than 100,000 hours |

|

Laser machine controller |

Reci |

|

Wobble welding head |

Single wobble |

|

Supply voltage |

Single-phase 220V±10%, 50/60Hz AC |

|

Machine power consumption |

11.5Kw(including chiller) |

|

Setting up the environment |

Flat, no vibration, no impact |

|

Working temperature |

0°C~40°C |

|

Working environment humidity |

≤80% |

|

Power adjustment range (%) |

10-100 (gradient adjustable) |

|

Laser Source Repeat frequency (KHz) |

1000-5000 (gradient adjustable) |

|

Beam quality |

1.3m2 |

|

Laser wavelength |

1070nm |

|

Focal length (mm) |

150 |

|

Cooling method |

Air cooling |

|

Size |

800x750x900mm |

|

Weight |

65kg |

|

Fiber length |

10 meters |

|

Welding head weight |

1.5Kg |

|

Scanning/Swing frequency |

20-150Hz |

|

Mobile mode |

Handheld |

|

Auxiliary gas |

99.99% argon or nitrogen |

|

Auto wire feeder |

Included |

|

Spot adjusting range |

0-5mm |

|

Repeating Precision |

0.01mm |