- Front page

- About Us

- Laser machine

Fiber Laser Cutting Machine

Fiber Laser Cutting Machine

Laser cleaning machine

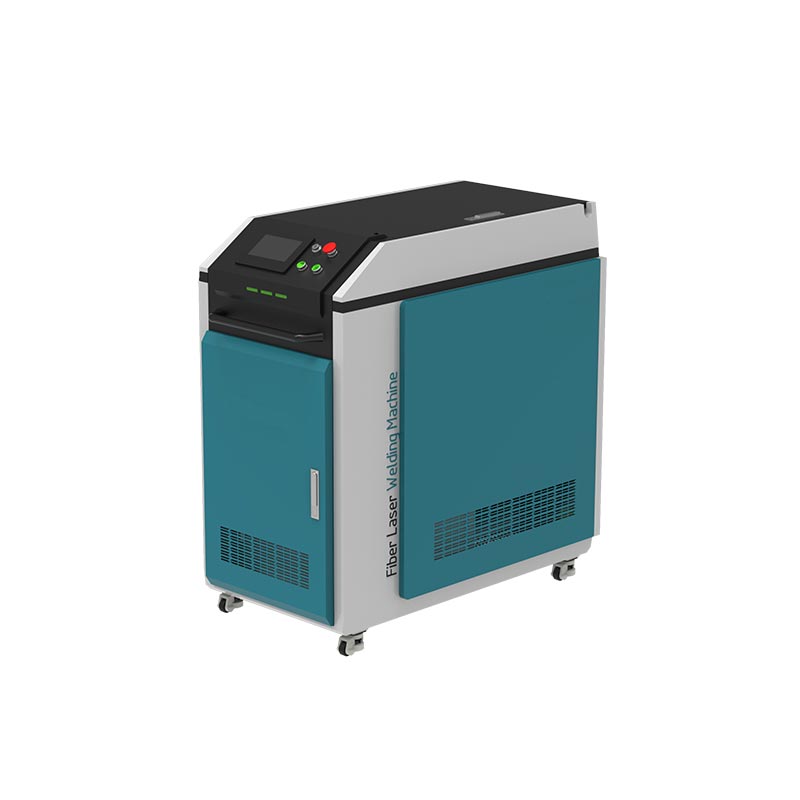

Laser cleaning machine Laser welding machine

Laser welding machine Bending Machine

Bending Machine

- Accessories

- Application

- Contact Us

- Featured

Working rolls are the main components of the plate rolling machines.When the hydraulic and mechanical force works on the rolls,the sheets and plates can be bent to curved shapes.

The worm wheel is used to drive the rolling reel to rotate faster,greatly affecting the rolling efficiency.

The motor is the main part that drives the upper and lower rolls to work.

The reducer connects with rolls from the upper and lower position to deliver torque.It helps to maintain constant acceleration and torque.

A plate rolling machine is a machine that can roll metal plates&sheets into circular, curved shapes.It has been used a many industries and there are three types of rolling machines from LXSHOW,including mechanical,hydraulic and four rolls.

A rolling machine works by using rolls to bend the plates and sheets into the desirable shapes.The mechanical force and hydraulic force work on the rolls to bend the material into oval,curved and other shapes.

When it comes to transmission mode,a mechanical plate roller machine is driven by the mechanical force while a hydraulic plate roller machine is using the hydraulic transmission.Additionally,it does not have prebending function compared with the hydraulic plate roller machine.

Carbon steel,stainless steel,aluminum,copper,high-carbon steel and other metals

The plate rolling machines have been used in industries, such as automotive, construction, shipbuilding,home appliance.

1.Construction:

The plate rolling machines are often used to bend roofs,walls and ceilings and other metal plates.

2.Automotive:

The plate rolling machines are widely used for fabricating the automotive parts.

3.Home appliance:

The plate rolling machines are commonly used to work on the metal covers of some home appliances.

For the plate rolling machines,we offer a three-year warranty and 2-day training.

Contact us to find more now!