- Front page

- About Us

- Laser machine

Fiber Laser Cutting Machine

Fiber Laser Cutting Machine

Laser cleaning machine

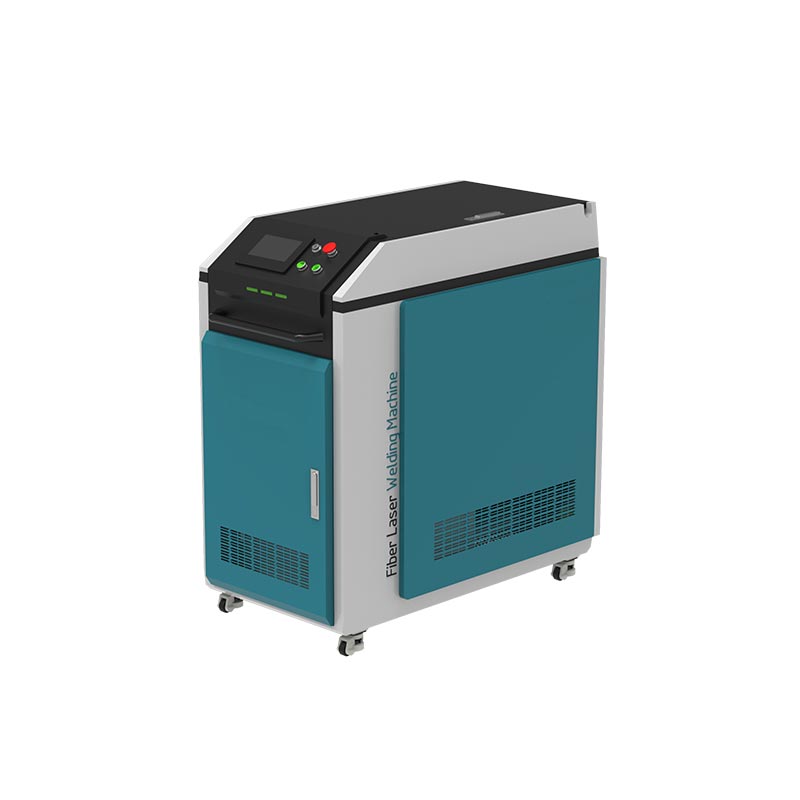

Laser cleaning machine Laser welding machine

Laser welding machine Bending Machine

Bending Machine

- Accessories

- Application

- Contact Us

- Featured

Hydraulic system

Adopts advanced integrated hydraulic system reduces the installation of pipelines and ensures a high degree of reliability and safety in the operation of the machine.

The speed of the slider movement can be realized. Rapid descent, slow bending, fast return back action, and fast down, slow down speed can be adjusted appropriately.

Electric control system

Eletrical component and material meet international standards,safe,reliable and long life.

The machine adopts 50HZ, 380V three-phase four-wire power supply.The motor of machine adopts three-phase 380V and the line lamp adopts single phase-220V.The control transformer adopts two-phase 380V.The output of the control transformer is used by the control loop, among which 24V is used for back gauge control and for electromagnetic reversing valves. 6V supply indicator, 24V supply other control components.

The electrical box of the machine is located on the right side of the machine and is equipped with a door opening and power-off device.The operate component of machine are all concentrated on the electrical box except the foot switch, and the function of each operating stacked element is marked by the image symbol above it.It can automatically cut off the power supply when opening the electric box door, and if it needs to be repaired live, it can be manually reset to pull out the micro switch lever.

Front and back gauge

Front bracket: It is Placed on the side of the worktable and secured by screws. It can be used as a support when bending wide and long sheets.

Back gauge: It adopts back gauge mechanism with ball screw and linear guide is driven by servo motor and a synchronous wheel timing belt. The high-precision positioning stop finger can be easily moved left and right on the double linear guide rail beam, and the workpiece is bent "as you like".